| Product Types Used | Belt Cleaning Solutions , Primary Belt Cleaners |

|---|---|

| Solutions | Mr. Blade® Program |

| Industry | Aggregate |

| Customer | Large fracking sand plant in Texas |

Problem

A large fracking sand plant in Texas with 5MM TPY capacity was experiencing serious carryback issues on its main conveyor, with wet sand clinging to the belt. The material would either transfer to the bend pulley, fall to the ground or fall into the take-up pulley where it would damage the belt. Cleanup was needed almost every day, at times becoming so bad that the process would have to be shut down for maintenance. Even worse, the material would drop from the belt, throwing sand into the air, causing health concerns over air quality. The results included lost material, wasted labor for cleanup, system downtime and employee safety, all of which impacted plant efficiency and profitability.

Solution

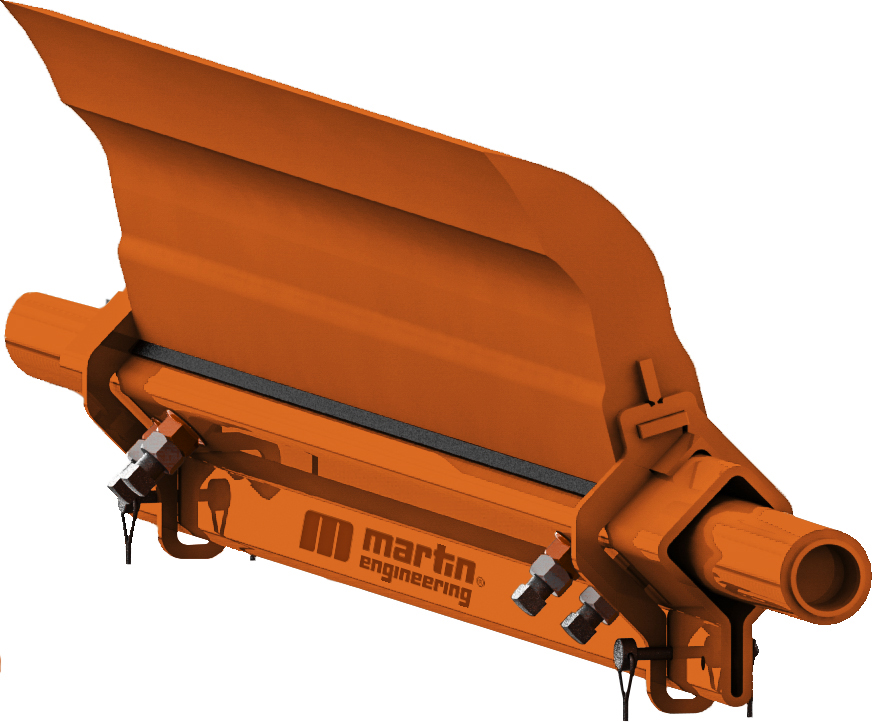

Mr. Blade technicians from Martin Engineering first ran a carryback capture test on the belt during normal running conditions. The material loss was found to be 4,255 short tons per year, easily enough to justify the expense of new belt cleaners. They installed a QB1™ Primary Cleaner on each end of the reversing conveyor, a heavy-duty design that features a no-tool replacement process that can be performed safely by one person in less than five minutes. A Scorpio Secondary Cleaner was also installed on each end. They replaced competing designs that were poorly matched to the application and incorrectly installed.

Results

Once the installations were complete, another carryback capture test was conducted to compare against the baseline test. It demonstrated a 78% reduction in carryback, for an initial savings of nearly $30,000 in lost material, which translated to annual sales of more than $400,000. Manpower and downtime for cleaning have been drastically reduced by the new cleaning solution. During the following months, the Mr. Blade technicians also replaced cleaners on all of the facility's silo belts, silo feeders, tripper cars and weigh belt feeders. All onsite units have been tagged using Martin's QR code system to track conveyor details, cleaner performance, & operational information.